What if we told you that a revolution is happening in the world of drying laundry, one that involves cutting-edge technology and automation? Welcome to the world of automated laundry systems, where Steigen is at the forefront of innovatively changing the way we dry our clothes.

In this article, we will dive into the quality control Steigen revels in, comparing system material, internal specifications, features and more against Brand XYZ to help you understand why we do what we do.

1. Fan Motor

All Steigen automated laundry systems have BLDC fan motors. As compared to AC motors, BLDC motors offer consistent stable fan operation, low noise, and overall better durability. Plus, general BLDC fan motors use 70% lower energy consumption too. Compared to outdoor 3.5m/s wind speed, BLDC fan motors produces an average of 6.9m/s and generates up to 1.5m air volume in length.

Not only do AC motor consumes more energy–resulting in higher electrical bills–but they are subject to tremendous wear and tear with continuous operation and would require more frequent maintenance.

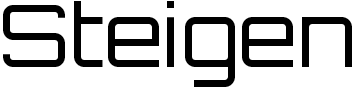

2. Air Volume coverage

Did you know that angled fan blades push more air volume out as compared to straight fan blades? The 4 full-size BLDC fans in a Steigen automated laundry system are made up of angled fan blades which blow in 8 different directions. The orientation of angled fan blades allows wind to blow in 8 different directions when in movement. This continuous 3h/6h cycle provides an even air volume coverage (CFM) of more than 175, 000cm³.

These 4 BLDC fans are split into 2 rows that result in zero blind spots when drying laundry. Hence, no shifting of clothes around the system in order to find an "optimal" drying spot.

3. Heater

As the saying goes, the more the merrier. Long heater coils generate more heat energy, resulting in more heat distribution to the laundry. Coupled with strong fans, this would encourage laundry to dry fast.

When the heater coils are shorter, lesser electrical energy is converted, in turn, producing less heat energy. The amount of heat and speed of drying are correlated–a smaller amount of heat would result in slower drying.

4. Ioniser

Steigen takes multifunction to the next level. The 2-in-1 Sol Ion™ combats musty laundry odours and reduces the breeding and feeding cycles of dust mites on laundry. Across the automated laundry system industry in Singapore, Steigen is the only brand offering a trademarked ioniser that produces both positive and negative ions at 25,000 ions/cm³.

Most of the other automated laundry brands in Singapore only offer negative ions to neutralise odour. The combination of both positive and negative ions is ideal to neutralise odour-causing allergens and more thoroughly.

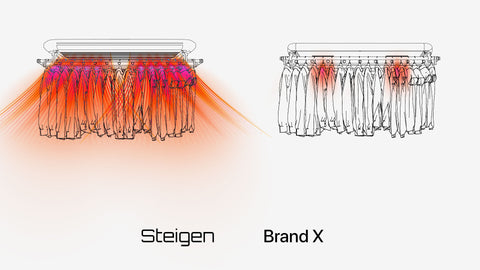

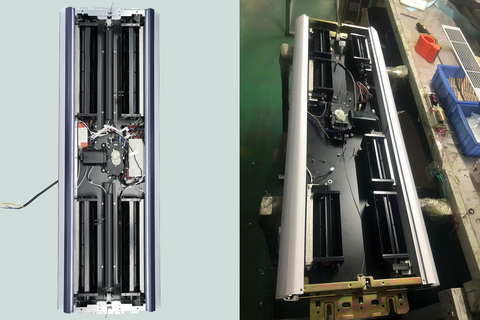

5. Mounting body frame

Steigen has always believed in producing a system material that focuses on high-temperature resistance, high corrosion resistance and high tensile strength (resistance to breakage).

Fun fact: Steigen is the only automated laundry system brand in Singapore to use SS304 stainless steel backboards for the systems to ensure maximum stability and durability. The 1.0mm blackboard is engineered to withstand various vigorous mechanical movements.

On the other hand, Brand XYZ use yellow zinc/mild steel and is susceptible to rust when exposed to moisture and high humidity. Due to its thin and malleable material, the backboard is prone to warp over time, reducing the overall system stability.

Unknown to most, straight-blade fans combined with small fan turbines will hugely discount the heat distribution around the system. Drying coverage would only be approximately 100, 000cm³ and under.

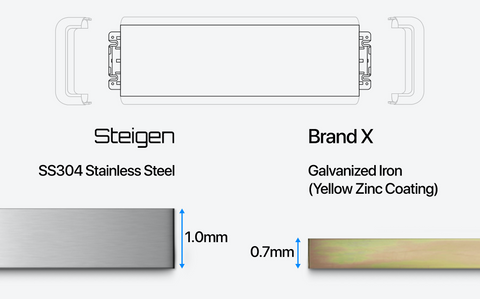

5. Electrical wiring

Product safety has always been paramount for Steigen. One of the key reasons for using thicker wiring is to cater to allowance for possible energy surges.

Compared to thick wiring, thin wiring holds lesser current and wattage. If the same amount of energy goes into the wire, the temperature will increase and might result in overheating and system malfunctioning.

Hence, you may discover that Steigen is the only automated laundry system brand in Singapore that uses 1.5mm2 cables for their systems.

Fun fact: HDB light points are 1.5mm2 to. The best safety practice is to go with appliances that can provide identical cable wiring sizes and nothing smaller.

6. Cable protection guards

Going another step further, Steigen's automated laundry systems also include cable protection guards to house these cable wiring. It protects both users and internal system components against potential electric shock.

When the up-down lifting motor is in motion, exposed wires are likely to move and come in contact with the other internal components. Such a contact would result in a power trip or electrostatic to be spread across the entire rack, making it a live conductor of electricity.

Steigen is the only brand in Singapore to design and build automated laundry systems with internal cable protection guards too.

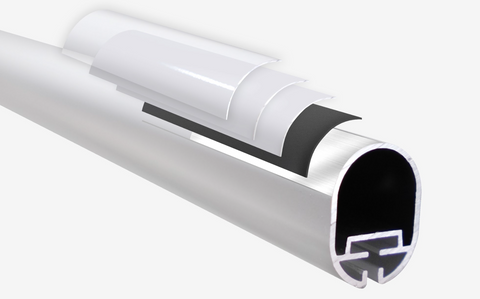

8. System coating

Nano-ceramic coating provides colour protection and resistance to corrosion. Overall, this method increases durability against wear and tear. In Singapore, Steigen is the only brand to provide nano-ceramic plating on automated laundry systems.

Conversely, powder plating has higher tendencies of decolouration, peeling and rusting. The powder plating would peel off within a year or two.

Only the best for the best

As technology continues to advance, you can expect even more innovations from Steigen. On top of embracing the future of drying laundry, go ahead and check out our Group Buy deal that's available for all housing estates–BTOs, resale flats and even condominiums.

Based on research done in Singapore across 21 automated laundry systems between Steigen and various brands. As of date of publication (Sept 2023).